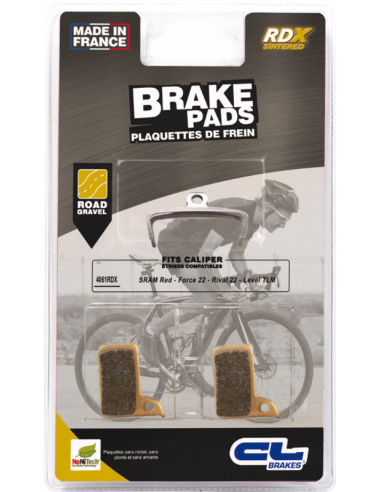

CL Brakes sintered pads are, in short, a synthesis of the best of metal and the best of organic pads, while eliminating the defects of each one of them.

Only sintered metal pads can respond to every demanding rider's need:

high braking power

low heating

good reaction to low temperatures

use under water, mud and dust

without noise

These are manufactured with up to 10 noble metals (such as bronze, iron, copper ...) in addition to other compounds such as graphite (derived from carbon), or even ceramic. However, these are Nickel Free as it is a hazardous material for health. Each of these components play an essential role in the friction of the pad with the disc, providing tact, avoiding noise and enhancing effectiveness. The pads are rectified, controlled and packaged under careful processes and ISO quality standards.

CL Brakes sintered pads are manufactured in France (Gennevilliers), providing maximum quality and confidence to the rider, in addition, since they are a very specific product aimed at the most non-conformist public, they are developed and tested in competition.

RDX finish:

New disc brake systems for road bikes also require new high performance pads. CL Brakes specially designed these RDX sintered pads for road and gravel bikes. Its composition and structure guarantee excellence in terms of performance, making the most of the caliper and disc :

- Convenient

- Strong initial bite, hot or cold

- Low noise

- Progressive feel